Work in Progress WIP Inventory Formula + Calculator

24/12/2024 21:14

For instance, the WIP inventory could be undergoing finishing touches prior to being marked as complete.

What are inventory Holding Costs? Formula & Tips to Reduce

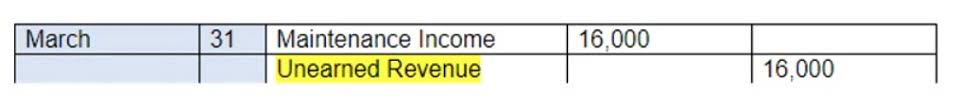

In this journal entry, raw materials and labor costs will only include the cost of raw materials and labor that is directly involved in the production. This is due to the indirect raw materials and indirect labor are considered the manufacturing overhead. These three cost elements are accumulated as products move through various stages of production. Properly accounting for these costs in WIP is important because raw materials gain value as labor and overhead are applied during the manufacturing process.

What Does G&A Stand For in Accounting?

A reliable supplier ensures consistent lead times, minimizes production delays, and reduces the risk of stockouts. When sourcing, prioritize suppliers with a strong track record in on-time delivery, quality control, and responsiveness to demand fluctuations. Building strategic supplier partnerships also enables better coordination on reorder points, safety stock levels, and production scheduling. WIP inventory is usually calculated periodically or at the end of the financial year for accounting purposes. While this ensures balanced books, it doesn’t go a long way toward actual control over the WIP inventory throughout the manufacturing process.

Managing and tracking WIP inventory

However, as the company moves gears into the production line and starts painting, raw materials inventory is reduced, and a new category of inventory called Work in Process arises. Keep in mind that manufacturing companies can use the perpetual inventory tracking method to keep track of their direct material inventory. For example, components that a computer manufacturer needs to assemble laptops may have serial numbers. Those numbers are scanned in when components are purchased from the manufacturer. Understanding WIP is essential for businesses aiming to streamline operations, improve cost control, and accurately assess production efficiency.

Taking time to classify WIP inventory in a warehouse waiting to be assembled might seem tedious, but it’s crucial for monitoring and improving your supply chain and inventory control. While work in process and finished goods refer to various stages in an inventory’s life cycle, they have clear distinctions. The term work in progress (WIP) describes inventory that is partially finished and currently amid the production cycle. Gain clarity on valuing your production assets and optimizing financial reporting. As part assets = liabilities + equity of the Keys Logistics marketing team, Sophie Hayes specializes in content strategy and industry insights.

Auditors are more likely to engage in a close examination of the accounting records for work-in-process when the ending valuation in this area is quite high, which can result in increased audit fees. Consequently, it pays to flush as much WIP into finished goods as possible prior to the end of Mental Health Billing the fiscal year. Generally, most companies strive to reduce the amount of time that inventory spends at the work in progress (WIP) stage. The formula for calculating work in progress inventory – in the specific context of a manufacturer – is as follows. On the income statement, the sale of the product would be recorded in the cost of goods sold (COGS) line item. WIP stands for “work in progress” and refers to any partially complete inventory not yet ready to be sold to customers.

Accounting for Manufacturing Company Inventory

- This value is essential for accurately determining the ending WIP inventory using the formula.

- During production, the cost of direct labor and overhead is added in proportion to the amount of work done.

- However, as the company moves gears into the production line and starts painting, raw materials inventory is reduced, and a new category of inventory called Work in Process arises.

- Finished goods are products that are completely done and ready to go out the door.

- WIP is considered a current asset on a company’s balance sheet, reflecting the value of partially completed goods at a specific point in time.

The total manufacturing costs we need to account for include the $345,000 costs in July, plus work in process from June. Most likely, those products were finished in July (although that’s not necessarily true). In any case, for July, we have the $66,000 in work in process carried forward plus $345,000 in new costs for a total of $411,000. Work in process also includes direct and indirect labor and other manufacturing overhead costs.

- Some companies do a physical count of their WIP inventory to determine the value based on the current stage of each unit in the manufacturing process.

- Materials consist of items in inventory that have not yet been entered into production or used.

- The manufacturing overhead during the period, including indirect raw materials and indirect labor, is determined to be $10,000.

- WIP encompasses raw materials that have entered the production line and are being transformed into finished goods.

- Actual costs are difficult to trace to individual units of production, unless job costing is being used.

- WIP is considered a current asset in the company’s balance sheet and represents the total value of all materials, labor, and overhead of the unfinished products.

Use a 3PL to support to inventory management

- Once the product is marked as a finished good and is subsequently sold, the appropriate amount is removed inventory balance on the balance sheet.

- To clarify where WIP inventory falls in the production process, let’s look at it in the larger context of other inventory classifications.

- Accurate accounting involves calculating the value of raw materials, labor, and overhead costs incurred up to a specific point.

- In the same period, it also incurs the direct labor cost of $25,000 and the indirect labor cost of $2,000.

- By following these steps, you can systematically calculate your WIP inventory and have a clearer understanding of your production process and current assets.

- In other words, it is the WIP asset section of the balance sheet of the previous accounting period.

While work in progress focuses on milestones, WIP aligns more with production efficiency and inventory management. Tracking the status of in-process goods and work orders is crucial to ensure efficient production processes and optimal stock levels. Doing this with spreadsheets or pen-and-paper is possible for very small or simple operations. However, a much more comprehensive solution for companies of any size lies in manufacturing software. The beginning work-in-process inventory represents the work in process inventory account of a manufacturing company the value of all unfinished goods at the beginning of the new accounting period.

Barcode/QR code tracking

In a logistics and supply chain context, WIP includes raw materials that have entered the production line and are undergoing transformation but are not ready for sale or final delivery. Work in process (WIP), sometimes called work in progress, is a type of inventory that lies in the manufacturing pipeline between the raw materials and finished goods inventories. In other words, WIP is the part of a company’s overall inventory that has begun being processed but is not yet finished. In accounting, WIP is an asset and designates the value of unfinished goods at the end of a financial period. Work in process (WIP) inventory refers to materials that are waiting to be assembled and sold. WIP inventory includes the cost of raw materials, labor, and overhead costs needed to manufacture a finished product.